Introduction

Ever felt like your projects are stuck due to inefficiencies and wasted resources?

If you are nodding in a yes, you are not alone. As someone who has over a decade of experience leading teams and managing projects, I’ve seen how complicated processes, budget overruns, and delays can hold a team back.

However, Lean project management can help! At ProofHub, we adopted Lean principles to streamline workflows, optimize resource allocation, and remove waste. This enabled our teams to provide high-quality results faster. Lean emphasizes efficiency without sacrificing quality, which helps our teams complete projects more quickly and with fewer resources.

Curious about how Lean can benefit your projects?

Below, I’ll explain all you need to know about the Lean project management method, including its definition, benefits, principles, and the tools you’ll need to put it into practice effectively.

Based on my experience, I can certainly state that whether you’re leading a small team or managing large-scale projects, using a lean approach can help you enhance productivity and success for your company. So let’s get started!

What is Lean project management?

Lean project management is a methodology that works on a straightforward concept of maximizing value while minimizing waste. It focuses on delivering the highest quality results using the least amount of unnecessary effort, time, or resources. The core idea is to eliminate anything that doesn’t add value to the project and streamline processes to boost efficiency.

Originally, it was developed in the manufacturing industry by Toyota in the 1940s. With the aim to eliminate inefficiencies and streamline workflows, they also introduced the concepts of Muda(waste), Mura(unevenness), and Muri (overburden). Where the Muda refers to any activity that consumes resources but doesn’t add any value in return, Mura focuses on the inconsistency in workloads, outputs, and processes and Muri happens when team members are pushed beyond their capabilities leading to excessive stress, burnout, and lower productivity.

Lean manufacturing principles were designed to optimize production by removing waste and improving workflow. However, these concepts are now widely adopted in project management across industries. Lean focused on cutting costs, improving efficiency, and creating more value for customers.

In project management, this involves reducing unnecessary meetings, excess documentation, and other distractions that slow teams down. Lean principles keep everything balanced and let companies deliver projects faster and more efficiently.

Read more: Guide to lean six sigma in project management 2026

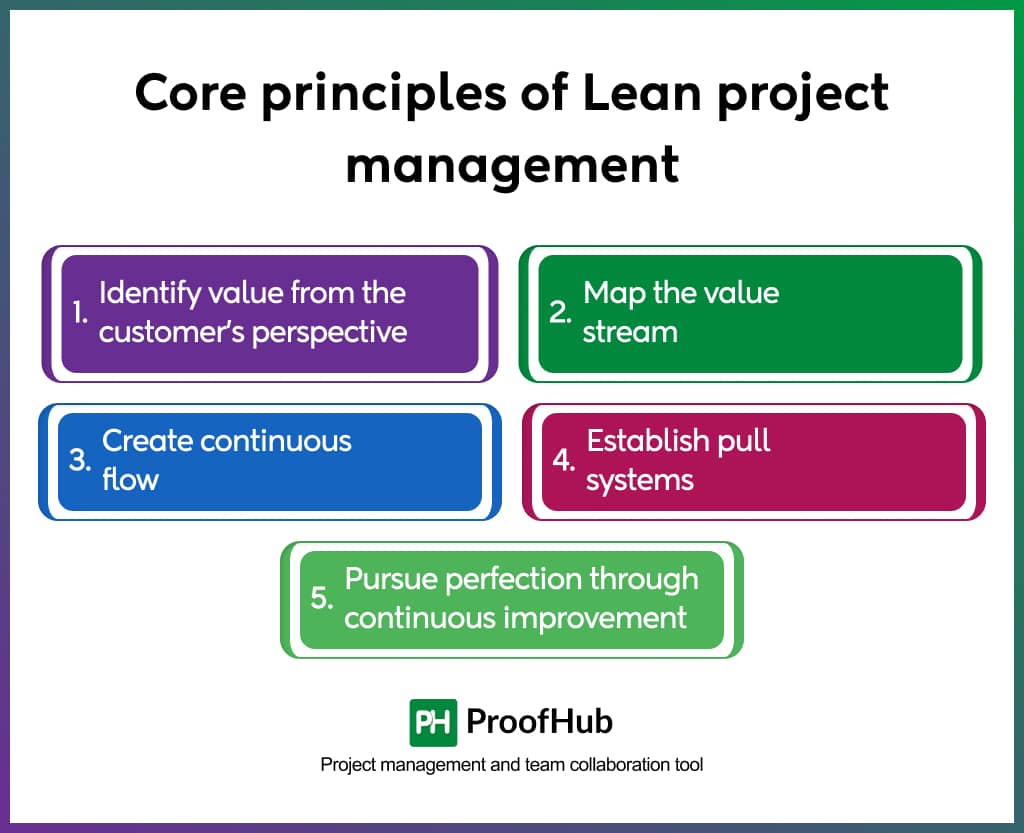

Core principles of Lean project management

Lean methodology project management encourages teams to streamline processes, focus on what is important to customers, and continuously improve their workflow. The Lean principles allow project teams to deliver products or services that meet customer needs efficiently, without unnecessary steps or delays.

Lean project management works on five core principles, each of which contributes to creating a more efficient, customer-centric workflow. Let’s dive into these principles and see how you can apply them in your processes.

1. Identify value from the customer’s perspective

The first principle of Lean development project management is to identify value, which entails understanding the demands of a customer.

Put yourself in the shoes of the customer and ask yourself, “What does your target consumer need, and how can your product or service help them?”

Customer-centricity is a fundamental concept of Lean. It is about providing both a product and value from the perspective of the customer.

In today’s fast-paced world, where 63% of customers want businesses to understand their specific needs and expectations, teams need to keep their focus on client needs.

When teams clearly define the value from the customer’s perspective, they set meaningful project goals and drive success.

Your project’s success is based on how well it meets customer needs. Therefore, you need to understand your customer requirements to define your project goals.

Right questions and feedback can help you align your processes and goals to deliver outcomes that are customer-focused. This improves project efficiency and increases customer satisfaction.

2. Map the value stream

A value stream is a sequence of activities that takes a product or service from its initial concept to delivery. In Lean, you need to map out this process and analyze each step. This will help you determine which step adds value and which does not.

Visualization helps you see the entire workflow, from idea generation to the final product. A value stream map highlights each stage of the project process, making it easier to identify inefficiencies and streamline processes.

Lean focuses heavily on eliminating waste. Waste can be anything that doesn’t directly contribute to the success of the project. This involves waiting times, unnecessary steps, or overproduction.

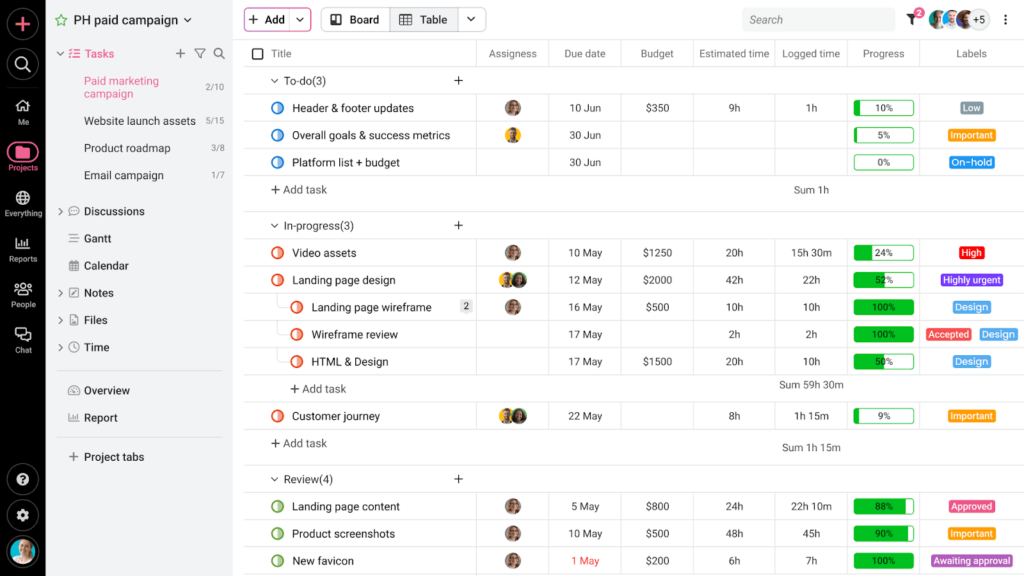

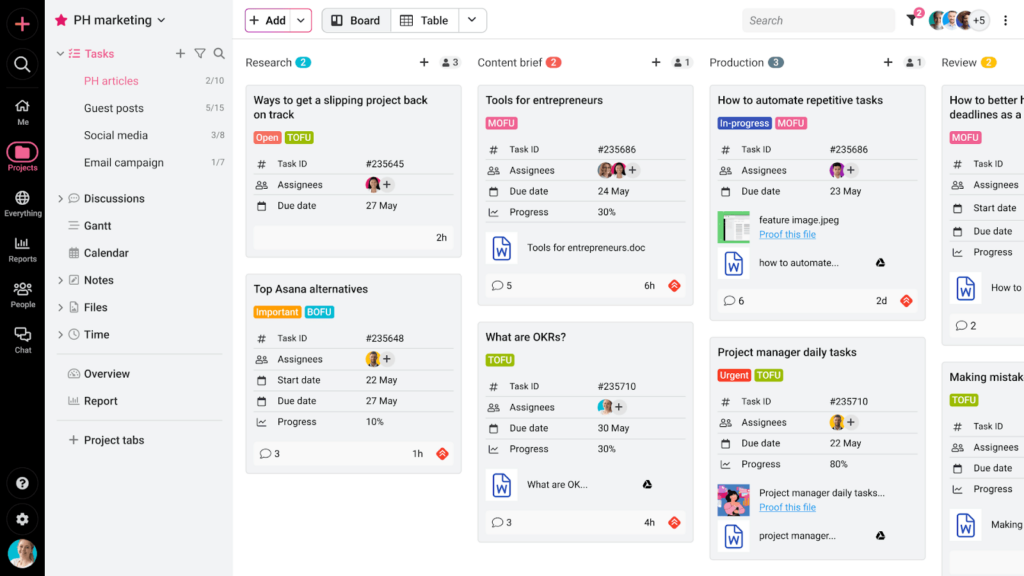

A task management tool like ProofHub can help you visualize your workflow, track project progress, and identify bottlenecks and inefficiencies. ProofHub is a project management and team collaboration tool with robust task management and reporting tools. It allows you to optimize your value stream and focus on delivering what matters most.

3. Create continuous flow

Next, you need to make sure that tasks move smoothly from one stage to the next without any interruptions, delays, or bottlenecks. Continuous flow helps you reduce delays and ensure that your project is delivered as efficiently as possible.

Bottlenecks are considered the biggest challenges in maintaining continuous flow. These include waiting for approvals, backlogs in work, or dependencies on other teams. Bottlenecks slow down the entire process. Kanban boards allow you to visualize tasks and identify potential bottlenecks, so you can address them before they cause any delays.

Kanban and Scrum techniques are used to create continuous flow in projects. These methods include visual boards and task prioritization to maintain the workflow.

Teams can maintain a consistent, productive pace throughout the product lifecycle by assessing workflows on a regular basis and dealing with any difficulties that occur.

Read more: How Kanban board project management can help you keep your project workflow on track

4. Establish pull systems

Lean favors the “pull” technique above the “push” approach. Whereas in the traditional project management style, work is often “pushed” through the pipeline with no consideration for what’s needed and hence put into waste or overproduction. A pull approach, on the other hand, means that work starts only after a proven demand exists for it.

A pull system helps teams avoid overproduction, a very common source of waste for many industries. Teams are focused on providing customer value because they are only producing what the customer needs and at what time it is needed to avoid unnecessary work.

A pull system helps your teams stay focused on tasks that bring value. It also reduces stress by preventing work from piling up unnecessarily.

ProofHub provides Kanban boards to effectively implement a pull system, allowing you to take on new tasks only when there is capacity.

5. Pursue perfection through continuous improvement (Kaizen)

Lean is never a “set-it-and-forget-it” approach; it needs to be refined and improved to ensure long-term success.

Kaizen is Japanese for “continuous improvement.” It is one of the foundational components of Lean project management. Kaizen allows teams to maintain long-term improvements through constant analysis of performance with small modifications.

Kaizen teaches that success comes from a succession of small, incremental changes. This strategy maintains a culture wherein teams are always looking for ways to get better, thus more results-oriented operations aligned with client expectations are achieved.

While some very small changes add up to great outcomes over time, this keeps teams competitive and responsive.

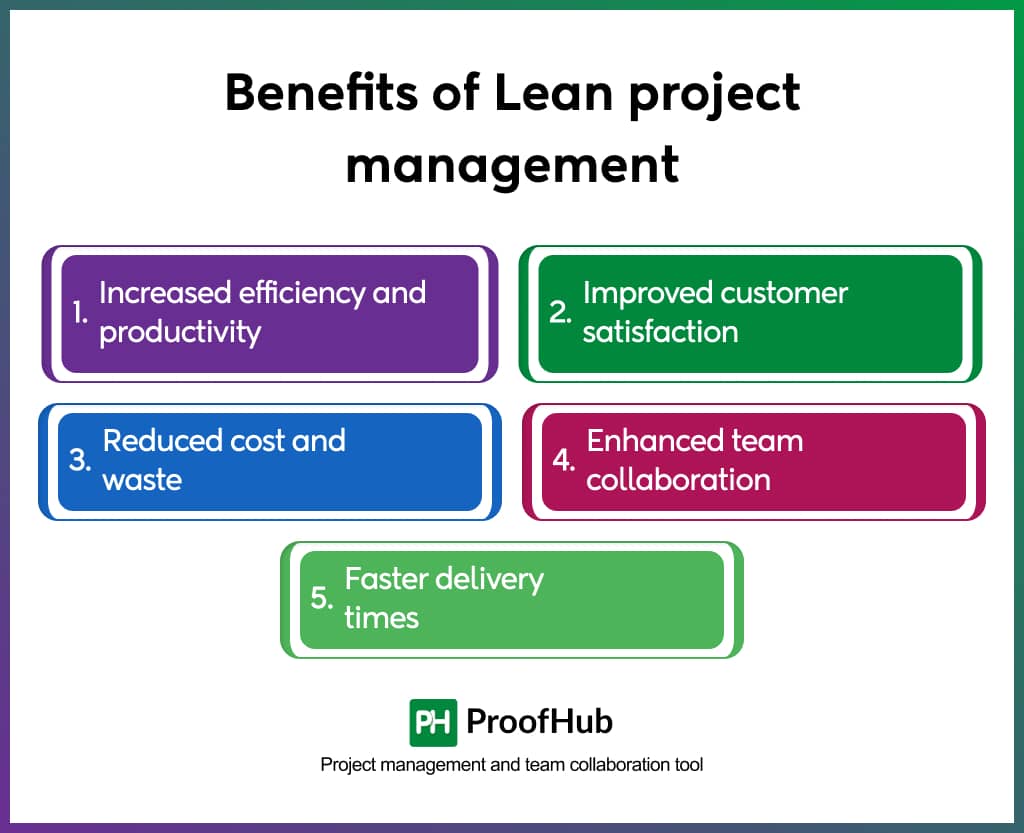

Benefits of Lean project management

Lean project management methods offer several advantages that help your teams operate efficiently and deliver projects on time. It eliminates waste and improves processes so that you can achieve more with less effort.

Here are some benefits of using Lean methodology in your project management process:

1. Increased efficiency and productivity

“Efficiency is doing better what is already being done.” – Peter Drucker

Lean takes this to heart, helping your teams do their best work in less time. It allows you to cut out unnecessary steps, materials, and efforts so that you can focus on more important tasks.

Companies that use Lean practices boost their productivity by up to 60%.

Yes! You read it right. The Lean approach lets your teams focus on tasks that add value, boosting productivity and efficiency.

2. Improved customer satisfaction

At its core, Lean means delivering exactly what the customer wants. It cuts out anything that doesn’t contribute to customer value. Thus, teams create products or services that meet or exceed expectations.

This customer-centric focus increases satisfaction and fosters long-term loyalty. When customers feel heard and receive what they need, they trust your organization more.

3. Reduced cost and waste

Lean focuses on removing waste – whether it’s time, resources, or unnecessary steps in a software development process, reducing the cost.

Companies using Lean can reduce operational costs by up to 50%.

You and your team save money by streamlining operations, avoiding rework, and using only what’s necessary.

4. Enhanced team collaboration and accountability

Lean encourages a collaborative culture in the workplace. Everyone shares responsibility and is accountable for both the successes and challenges of the project.

With open communication, team members can better align, communicate, and stay transparent in their efforts. This also facilitates finding issues early on and resolving them without affecting or compromising quality.

When everyone works towards common goals, projects run more smoothly and there are fewer conflicts among team members.

5. Faster delivery times

Teams can complete their tasks more quickly when there are streamlined work processes and fewer issues.

They don’t have to spend their time waiting for approvals or redoing tasks, thus meeting deadlines more consistently and efficiently.

Lean project management tools

Lean in project management focuses on maximizing value while minimizing waste. And, the right tools can help you achieve this.

These tools streamline processes, visualize workflows, and provide actionable insights for efficient project management.

Here are some essential Lean project management tools that can help you and your team stay efficient and continuously improve.

1. Kanban boards

The Kanban board is a visual workflow management tool that is integrated into Lean methodology. It allows you to break down your projects into tasks and represent them as cards on a board.

Team members can easily monitor the status of a task as it progresses through several stages (e.g., To Do, In Progress, Done). This tool encourages a constant flow of tasks. So that teams can spot any problems beforehand and make sure the project is delivered on time.

Kanban boards also support the Lean principle of pull, where a new task is only taken on when the team has the capacity. This prevents overload and allows you to keep a consistent pace, resulting in effective and sustainable project management.

2. Value stream mapping software

Value stream mapping (VSM) helps teams visualize the entire flow of a project from start to finish. By mapping out each step, VSM identifies areas of waste or inefficiency and helps teams streamline processes.

Traditionally, VSM was done on paper. However, nowadays, digital tools have taken its place. These tools make it easier and faster to map processes and update them as needed.

VSM software allows teams to visualize the value delivered at each stage. They ensure that every step adds value to the project.

3. Project management software

If you want to apply Lean to your daily project management, you need a tool that can handle multiple processes without any complexity.

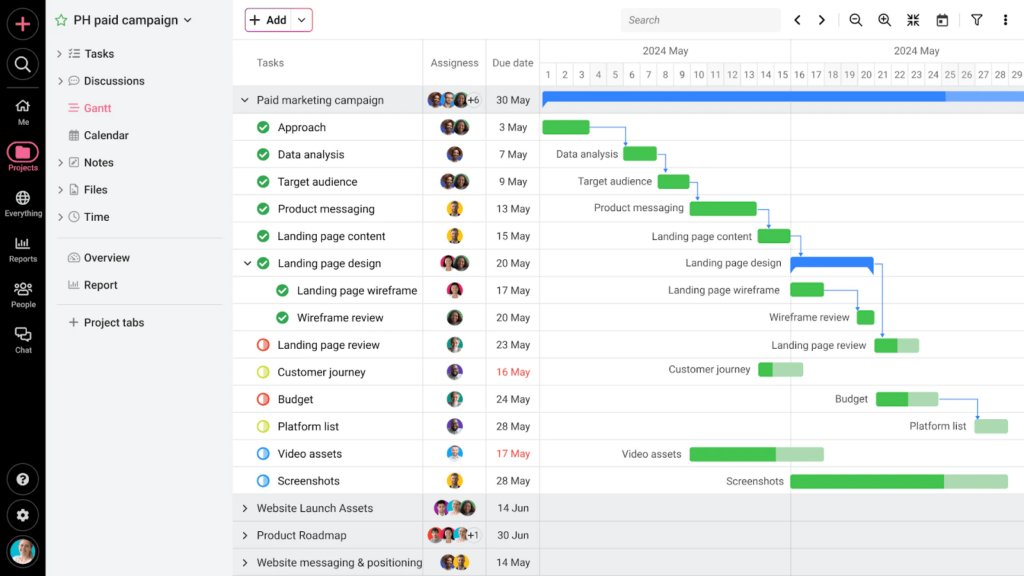

Project management tools support Lean methodologies by offering a unified platform for collaboration, task tracking, and reporting.

ProofHub is such an amazing tool for Lean software development and project management. It is an all-in-one project management and team collaboration software that brings Kanban boards, Gantt charts, task management, time tracking, team collaboration, and reporting tools together – in a single place.

ProofHub lets you streamline workflows, manage resources efficiently, and speed up project delivery. It allows you to efficiently implement Lean concepts by eliminating the need for several tools, saving time and effort.

4. Metrics and analytics tools

Lean project management emphasizes continuous improvement, and the best way to achieve this is through data. Metrics and analytics tools let you track progress and identify areas for improvement.

You can collect data on numerous aspects of the project like task completion rates, team performance, and logged times. This data helps you make data-driven decisions.

Regularly reviewing this data can help you identify inefficiencies and adjust processes accordingly. For example, analytics can assist you detect a particular task that is taking longer than expected. Thus you can streamline that step.

Read more: Project management tools and techniques that actually work

Conclusion

Lean project management provides numerous benefits, including waste reduction, increased efficiency, and continuous improvement. By focusing on delivering maximum value with fewer resources, Lean’s basic principles can be used across industries.

Whether you work in marketing, software, or operations, Lean project management scales to meet your demands and helps teams optimize their workflows.

FAQs

What are some common misconceptions about Lean project management?

A very common misconception about Lean project management is that it’s only for manufacturing. In reality, Lean can be used by any industry to reduce waste, improve efficiency, and deliver value.

There is one more myth that it’s too rigid, but Lean actually encourages flexibility and continuous improvement for better results.

How can small businesses benefit from Lean project management?

Lean project management can be a great help for small businesses. It optimizes their workflows, reduces costs, and delivers results faster. It allows teams to focus on what is relevant, work in a more efficient way, and optimize the use of resources.

Small businesses can enhance efficiency and ensure that projects are on track without making things more complicated than they ought to be.

What are the 4 P's of Lean?

The 4 P’s of Lean are Philosophy, Process, People & Partners, and Problem-solving.

They focus on long-term thinking (Philosophy), efficient workflows (Process), empowering and respecting team members (People & Partners), and a continuous improvement mindset (Problem-solving).

Together, they help you reduce waste and boost productivity in a smart, sustainable way.

What are the key metrics for measuring success in Lean project management?

In Lean project management, key success metrics you need to keep in mind are cycle time (how quickly tasks are completed), waste reduction (cutting unnecessary steps), team productivity, and customer satisfaction.

By focusing on efficiency and delivering value with minimal waste, you can track your progress and ensure projects stay on target.